OUR APPROACH

Gist Design specializes in industrial design and is dedicated to enhancing our clients' in-house capabilities by identifying gaps and aligning project resources as necessary. We maintain a small team and collaborate with a select group of independent industry experts who are highly skilled and truly passionate about their work.

Our role in a project is adaptable; we can manage the project, mentor your in-house team, or address specific gaps as needed.

A SIX SIGMA APPROACH TO DESIGN THINKING

Gist prioritize's efficiency and cost-effectiveness by utilizing a stage-gated approach to product development while embracing a lean design thinking process to achieve successful solutions.

PLANNING

Effective design begins long before production, and every project has its unique structure. However, all projects require careful planning and the ability to gather the right expertise. While our clients spearhead the transformation of their product ideas successful businesses, Gist Design and its partners are there to support them, share knowledge, and collaborate throughout the journey. By joining forces early on, we can collectively assemble the essential components to enhance your product’s value. With extensive hands-on experience in developing FDA products and operating in ISO 13485-certified environments, Gist recognizes the importance of adhering to a Quality Management System. Our in-house processes are structured with this principle in mind. We prioritize efficiency and cost-effect by employing a stage-gated approach to product development, integrating lean design thinking for optimal solutions. During the planning phase, we assess initial requirements, identify gaps, and recognize potential risks, ultimately crafting a tailored Scope of Work (SOW) that outlines the necessary research and conceptualization for a clear path forward. We continuously review and refine our plan at each project stage, our efforts and resources are directed appropriately. This is where we identify key “unknowns” in the project and strategize to mitigate them. At the core of our methodology, we aim deliver simple, appealing, and comprehensive solutions for clients that can seamlessly transition to their chosen manufacturer.

.jpeg)

PHASE 1

CONCEPT & FEASABILITY

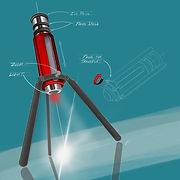

With a agreed to plan and scope in place, we will begin conduct any additional our research, generate ideas, assess feasibility, and develop clear Concept directions review and discussion. We will examine the overall aesthetics of the structure and enclosures, as well as the placement of internal components and systems. This process is typically iterative; we prioritize close collaboration with our clients, frequently sharing ideas to refine various concepts. Instead of overwhelming you with numerous options, we focus on establishing the success criteria for the concepts variations explored. This allows us to provide matrix to help identify the best way forward. The final outputs of phase will vary based on the agreed-upon scope of work, and may include research, photorealistic renders, animations, or feasibility reports.

%20(1)_JPG.jpg)

PHASE 2

DESIGN DETAILING FOR MANUFACTURING

Once the preferred concept direction is established, we will refine the designs towards suitable prototype and production technologies. Based on the chosen concept, Gist will evaluate various fabrication options and recommend a forward path considering the required performance characteristics, budget, lead time, and build projections. Refinements to the concept will enhance ergonomics, address assembly and panel separations, and ensure compliance with relevant regulatory and quality standards. Our in-house prototyping capabilities allow for rapid validation of solutions, followed by a formal design review and the of a functional prototype to identify any necessary adjustments before investing in production tooling.

PHASE 3

VALIDATION BUILD & PRODUCTION

Based on the feedback from the functional prototype, we will make design refinements to optimize parts for production tooling as needed. The design will be formaly frozen, and supporting documentation will be developed, including labeling and assembly guidelines. Manufacturing Partners will be selected and validated together, along with the assembly of initial pre-production units for Verification & Validation with third-party testing facilities.

PHASE 4

HUMAN FACTORS ENGINEERING

Creating products that cater to people's needs is fundamental to our mission. Human factors play a crucial role in ensuring the safety and efficacy of our products. In the development of medical devices, thorough documentation and external evaluations are vital and integrated throughout the product development lifecycle. Through Gist and our network of expert collaborators, we can assist with various Human Factors engineering activities, including: * Market & User Profiling * User Research; including focus groups and user observations * Risk Management as it relates to usability * Contextual Enquiry and observation * Preparation of Use Specifications(s) * Preparation of User-interface Specification(s) * Definition of Use Scenarios * Design of wireframes and screen templates * Design of training Materials * Device Labeling & Guidelines * Design of information and packaging including IFU’s * FMEA & FTA * Task Analysis * Device Verification & Validation Planning * Formative Evaluations * Summative evaluations

_edited.jpg)